Do you want to implement an environmental strategy but don’t know where to start?

A lot of companies, big and small, have implemented an environmental strategy. Some of these have been put together to satisfy the needs of shareholders, while others have been developed on the back of ISO14001 accreditation. Some, however, originate from a deep-rooted desire to make a real difference, changing systems and procedures and challenging staff behaviour - think M&S! But for a lot of companies, especially SMEs, the greatest challenge is not only knowing where to start but how to resource it. Like any good business strategy, the secret is about understanding your starting point – the ‘baseline’. We, at Green Gain, work with a variety of commercial, industrial and public sector organisations of varying sizes, spread across a host of geographic locations. Nine times out of ten, when you ask a senior manager in the business how much they spend on waste, water and energy consumption, the response is “I haven’t got a clue!” However, taking the time to unravel billing information and consumption data always reveals significant low or no cost carbon and cost-reduction opportunities, which then lead to more capital-intensive process enhancements. Herein lies the embryo of a business’s environmental strategy.

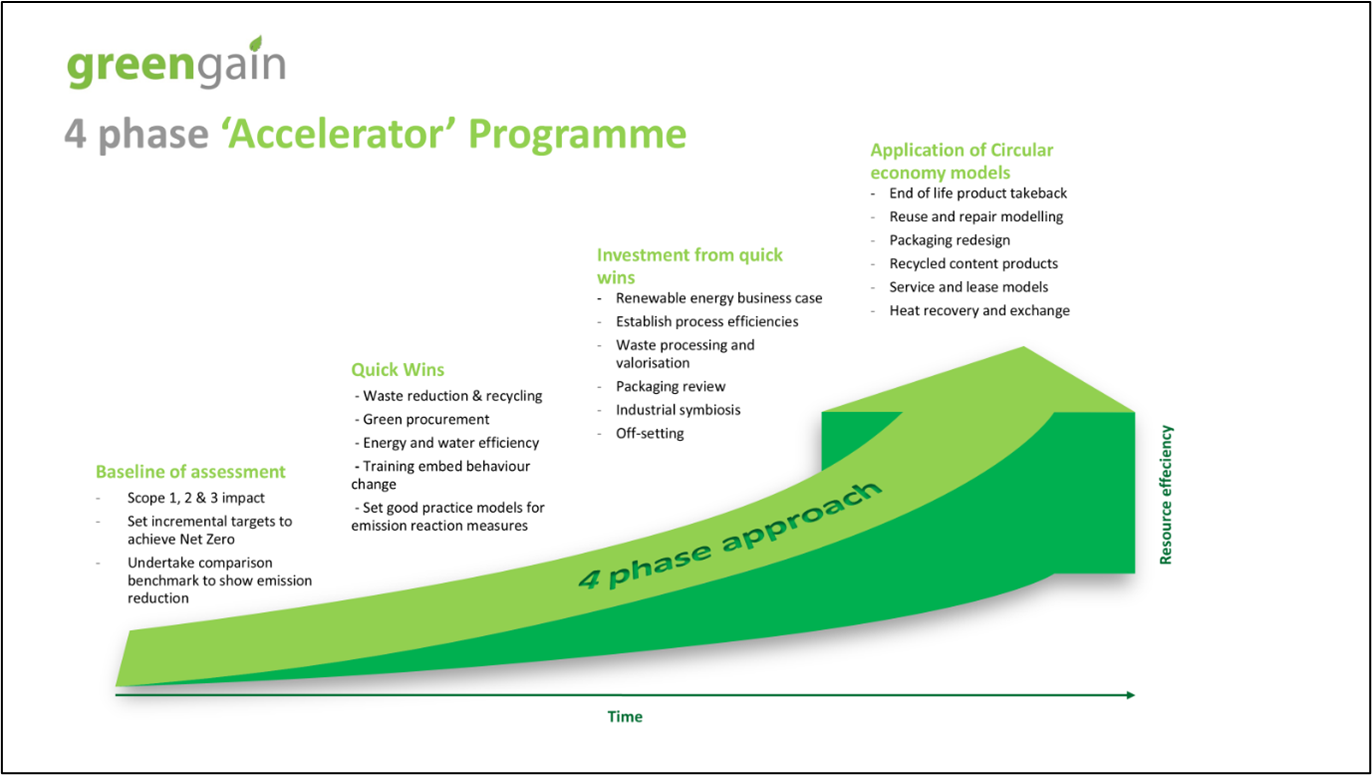

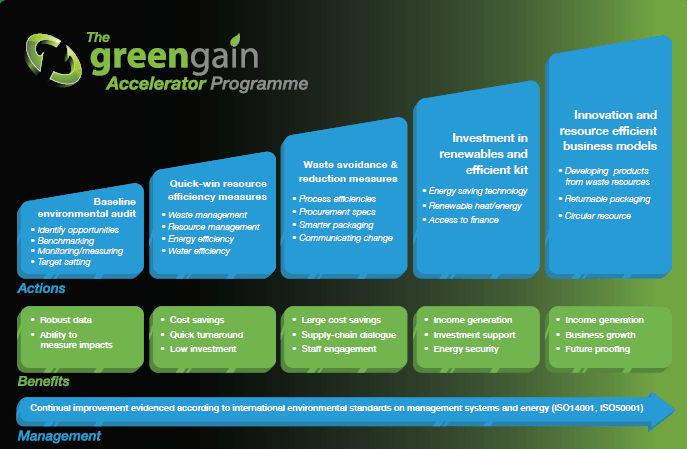

Having seen this all too many times, Green Gain decided to create a programme of support that addressed such a need; a cost-effective solution that pays for itself within a year that significantly reduces cost and a business’s carbon footprint. By way of example, Green Gain recently supported the UK’s leading manufacturer of high-quality deli-fillings, Fresh-pak Chilled Foods (based in Wombwell, Barnsley), to secure a top Asda sustainability award. This was achieved by engaging Fresh-pak in The Green Gain Accelerator Programme. The Accelerator takes businesses through a staged process of environmental improvement, enabling them to engage at different starting points and advance from there, depending on the systems they already have in place. The approach is ideal for SMEs that do not necessarily have the in-house time, resource and know-how to address their environmental impacts cost-effectively, or would like to introduce an environmental strategy but do not know where to start.

Fresh-pak started at the beginning of the Accelerator process, receiving support from Green Gain to develop baseline data across each of its impact areas, including energy, waste, water, and effluent. For the first time, the business had a robust understanding of its environmental impacts and the related costs, as well as the systems in place for ongoing monitoring. From here, it was possible for Green Gain to assist Fresh-pak to develop a strategy to for addressing these impacts. This included an action plan of prioritised recommendations across each impact area and clear roles and responsibilities for delivering these.

The initial priority was to address low and no-cost quick wins to build momentum, confidence, and to develop an investment budget from the resulting savings achieved.

From here, more expensive, long-term, innovative measures could be considered. Green Gain worked with Fresh-pak to develop a team from across various functions within the business to lead on the implementation of environmental impact reduction measures. Together, business cases were formulated for investment in areas such as:

·more efficient and effective processing equipment;

·improvements to heating and chilling systems; and

·new waste management infrastructure.

The opportunities with the clearest benefits in terms of simple payback, environmental improvement and benefits to overall quality improvements were pitched to the board, with investment secured for implementation. The systems in place for capturing baseline data have allowed Fresh-pak to monitor the impacts of these investments following implementation. This has enabled Fresh-pak to demonstrate its improvements to customers and to build the case for further ongoing investment in improvements.

As a result of engaging in the Accelerator programme, Fresh-pak has been able to reduce its costs, improve its efficiencies and productivity, and comply with the Energy Savings Opportunity Scheme (ESOS). It has managed to make its primary operations more sustainable. The business reduced its overall waste generation by 20% on the previous year and reduced landfill by 47%. It has also implemented investments on production efficiency and energy efficiency with simple payback achieved in less than 18 months. This support has now helped Fresh-pak to gain recognition from one of its key customers.

“As energy, waste and commodity prices continue to rise, sustainability is becoming an increasingly important issue. The work we are doing with Green Gain to address these issues is not only gaining us recognition with our customers; it is helping to secure our long-term future.” David Green, on behalf of Fresh-pak.